2. High pressure pump parameter:

| Design presure |

420Mpa |

| Continuous working pressure |

0-380Mpa |

| Max. oil discharge |

104L/min |

| Max. Flow rate |

3.7L/min |

| Power supply |

37Kw 50 Hp |

| Voltage |

customised |

| Orifice use |

0.25/0.28/0.30/0.33mm |

| Parts of intensifier |

from USA |

| Continuous working time |

24 hours |

| warranty |

12 months from the date of installation

except the wearing parts |

| Popular in |

Marble ,granite , aluminum,

copper , steel |

Attributes:

1 Imported assembling parts of intensifier from USA.

2 PLS from Siemens .

3 Low-pressure drilling and turn to High-pressure cutting automatically. This offer good protection for cutting class ,mirrors and tiles such fragile materials .

4Temperature sensor for over-high temperature protection

5 Automatic emergency stop for super-high pressure |

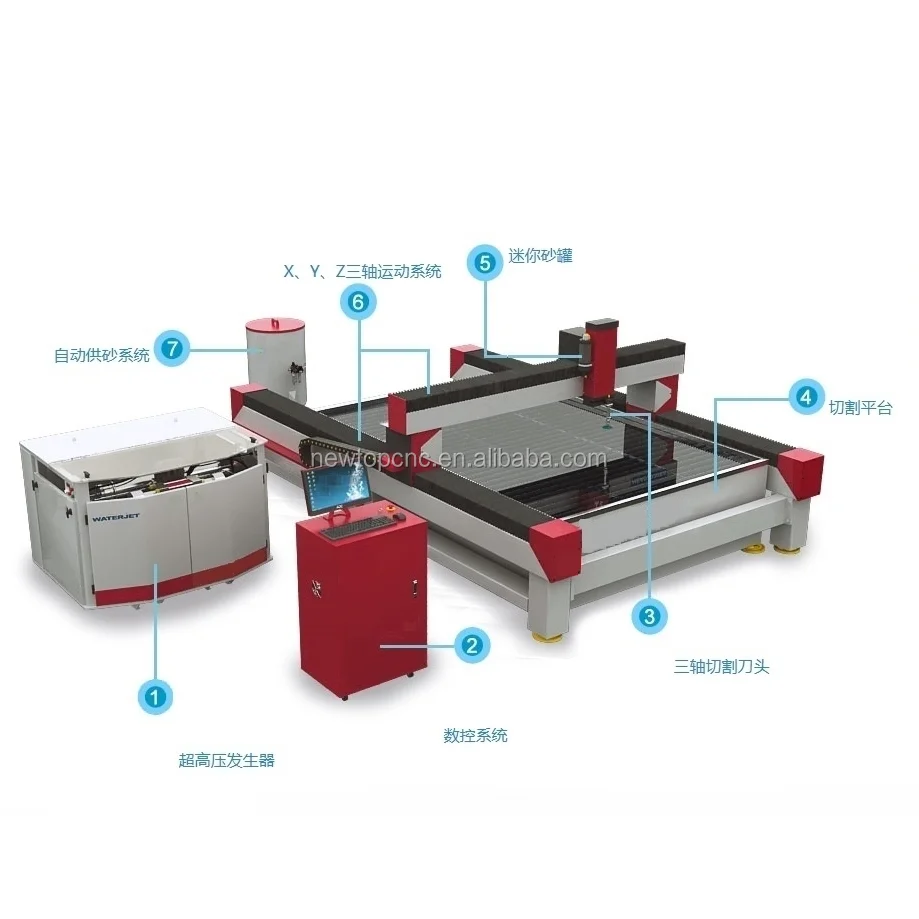

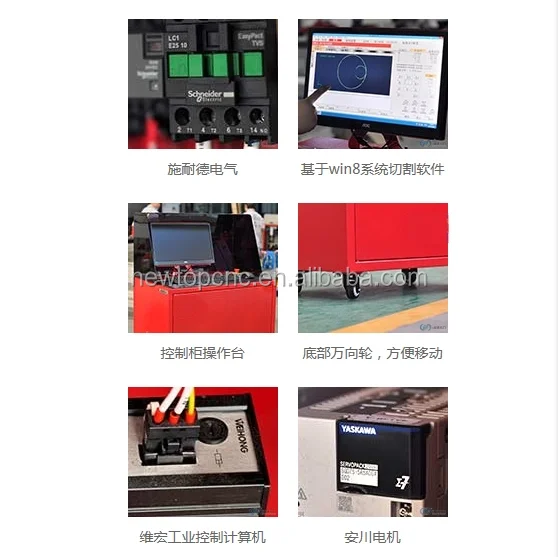

3. CNC control System :

| Control way |

CNC system |

| Size of displayer |

19 Inch LCD |

| Operation system |

Windows XP |

| Drawing system |

CAD |

| Professional waterjet software |

auto save and transfer common cutting parameter |

| Servo Driver |

Yaskawa ,Japan |

Attributes:

Professional IPC offers excellent protection against electronic interference and high-reliability

Professional five axis waterjet software with 2 languages version, easy for learning and operation.

Full Auto CAD DWG format support, automatically control code generation from DWG files.

Simulation runs can be used to double check for design flaws.

Automatically lead-in, lead out and corner compensation increase production efficiency and quality.

Remote control can provide an easy operation. |

4. Auto Abrasive feeding System:

1 Pneumatics technology support ,safe and reliable.

2 Abrasive flow-rate self-detecting function to support feed abrasive continuously .

3 store 200kg of sand at a time

4 can be used simultaneously for the two machines

5 auto alarming function

6 The Abrasive hopper with a new type of abrasive adjusted valve,supplies the cutting head with constant quantity of abrasive. Without this controlled supply, the mixing chamber for abrasive, air and water would become clogged up. With the abrasive adjusted valves , this is effectively cut down . |

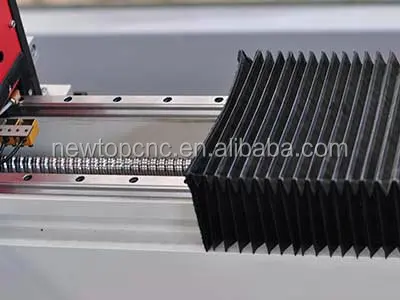

5. 3 axis cutting head

The cutting head Equipped with Screw ball which help to

improve the cutting accuracy .Use of nozzles of Ceratizit. |

6. Free spare parts and tools

Item Description Part No. Qty Application and remarks

1 Orifice 12.45*6.48*0.3 4 Used for cutting head

2 Outlet poppet H12022 2 Used for outlet check valve body

3 Insert H12021 2 Used for outlet check valve body

4 Poppet H12030 2 Used for check valve main body

5 O-ring 33.5×2.65 4 Used for end cap and check valve main body

6 Needle B type 1 Used for on/off valve assembly

7 Insert - on-off valve B type 1 Used for on/off valve assembly

8 High pressure valve seal B type 1 Used for on/off valve assembly

9 O-ring AS568-006 2 Used for needle

10 O-ring 8×1.9 2 Used for piezometric tube

11 O-ring 40×3.1 2 Used for low pressure oil pipe

12 O-ring 26.5×1.8 2 Used for end bell

13 O-ring 30×3.1 2 Hydraulic oil pip (HP)

14 O-ring 9×1.8 4 Used for signal pipe

15 Blue goop 1

16 Nozzle 1

pic:

payment: 30% T/T, 70% before shipment. delivery time: 25days after get deposit.

HS code: 84649011;

after service: